FV1200

High Speed Vertical Machining Center

Description:

FV-1200

X axis: 1200mm

Y axis: 660mm

Z axis: 610mm

-

(*請左右滑動觀看)

※Reserved technical modifications.MODEL FV 1200 TABLE Table size mm 1400 x 600 T slot mm CD100 x 18 x 5 Max. table load kg 800 TRAVEL X axis mm 1200 Y axis mm 660 Z axis mm 610 (810) Dis. From spindle nose to table mm 85~695 (85~895) Dis. From spindle center to Z axis telescopic cover mm 655 SPINDLE Taper #40 Speed RPM 10000 Power KW 11 / 15 SLIDE WAY Type Roller Type No. of slide way 2 / 3 / 2 Size of slide way #35 / #35 / #45 No. of blocks 6 / 5 / 6 Feedrate Cutting feed mm/min. 5000 Rapid Feedrate M/min. 48 / 48 / 32 ATC Tool No. 24 Tool shank BT/CAT/DIN #40 Max. tool dia.x length mm 75x300 #40 Max. tool weight kg 7 General Power capacity KVA 25 Air Pressure kg/cm 6 Machine Size (Door Close) mm 3000 x 2435 x 3100 Machine Size (Door Open) mm 4500 x 2435 x 3100 Machine Size(Max. floor space with chip conveyor) mm 4800 x 3685 x 3100 Machine Weight kg 7500 -

- FANUC Controller

- BT40 Belt Type Spindle 10,000rpm

- Graphical Auxiliary Functions

- 3-axis Cooling System

- Spindle Oil Cooler

- Cutting Coolant System

- Arm Type ATC 24 Tools (Frequency Conversion)

- Auto Lubrication System

- Full-Cover Enclosure

- Heat Exchanger For Electric Cabinet

- Remote MPG

- Coolant Gun/Air Gun

- Work Lamp/3-Color Indicator Light

- Tool Box

- Leveling Bolts & Blocks

-

- Belt Type Spindle 12,000rpm

- Direct Drive Type Spindle 12000/15000rpm

- Arm Type ATC 30 Tools (Frequency Conversion)

- Grease Lubrication System

- Link Belt Type Chip Conveyor

- Screw Type Chip Conveyor

- Internal Double Screw Chip Removal System

- Air Conditioner For Electric Cabinet

- Oil Skimmer

- Oil Mist Collector

- 4th Axis Rotary Table

- Tool Probe

- Workpiece Set Up Probe

- Linear Scale

- Transformer

-

※Reserved technical modifications. -

Chip Conveyor Floor Space

※Reserved technical modifications.

-

Specification(*請左右滑動觀看)

※Reserved technical modifications.MODEL FV 1200 TABLE Table size mm 1400 x 600 T slot mm CD100 x 18 x 5 Max. table load kg 800 TRAVEL X axis mm 1200 Y axis mm 660 Z axis mm 610 (810) Dis. From spindle nose to table mm 85~695 (85~895) Dis. From spindle center to Z axis telescopic cover mm 655 SPINDLE Taper #40 Speed RPM 10000 Power KW 11 / 15 SLIDE WAY Type Roller Type No. of slide way 2 / 3 / 2 Size of slide way #35 / #35 / #45 No. of blocks 6 / 5 / 6 Feedrate Cutting feed mm/min. 5000 Rapid Feedrate M/min. 48 / 48 / 32 ATC Tool No. 24 Tool shank BT/CAT/DIN #40 Max. tool dia.x length mm 75x300 #40 Max. tool weight kg 7 General Power capacity KVA 25 Air Pressure kg/cm 6 Machine Size (Door Close) mm 3000 x 2435 x 3100 Machine Size (Door Open) mm 4500 x 2435 x 3100 Machine Size(Max. floor space with chip conveyor) mm 4800 x 3685 x 3100 Machine Weight kg 7500 -

Standard Accessories

- FANUC Controller

- BT40 Belt Type Spindle 10,000rpm

- Graphical Auxiliary Functions

- 3-axis Cooling System

- Spindle Oil Cooler

- Cutting Coolant System

- Arm Type ATC 24 Tools (Frequency Conversion)

- Auto Lubrication System

- Full-Cover Enclosure

- Heat Exchanger For Electric Cabinet

- Remote MPG

- Coolant Gun/Air Gun

- Work Lamp/3-Color Indicator Light

- Tool Box

- Leveling Bolts & Blocks

-

Optional Accessories

- Belt Type Spindle 12,000rpm

- Direct Drive Type Spindle 12000/15000rpm

- Arm Type ATC 30 Tools (Frequency Conversion)

- Grease Lubrication System

- Link Belt Type Chip Conveyor

- Screw Type Chip Conveyor

- Internal Double Screw Chip Removal System

- Air Conditioner For Electric Cabinet

- Oil Skimmer

- Oil Mist Collector

- 4th Axis Rotary Table

- Tool Probe

- Workpiece Set Up Probe

- Linear Scale

- Transformer

-

Work Range

※Reserved technical modifications. -

Floor SpaceChip Conveyor Floor Space

※Reserved technical modifications.

Features

-

01Machine Structure

- Strengthened and widened column and base, increase the rigidity and stability.

- 3-linear roller type linear guideway in Y axis(Base), improve the dynamic accuracy and rigidity, keep stable. It is obvious when machining with 4th axis rotary table and tailstock.

- 6 blocks in X axis linear guideway(work table), improve the dynamic accuracy and rigidity, keep stable.

-

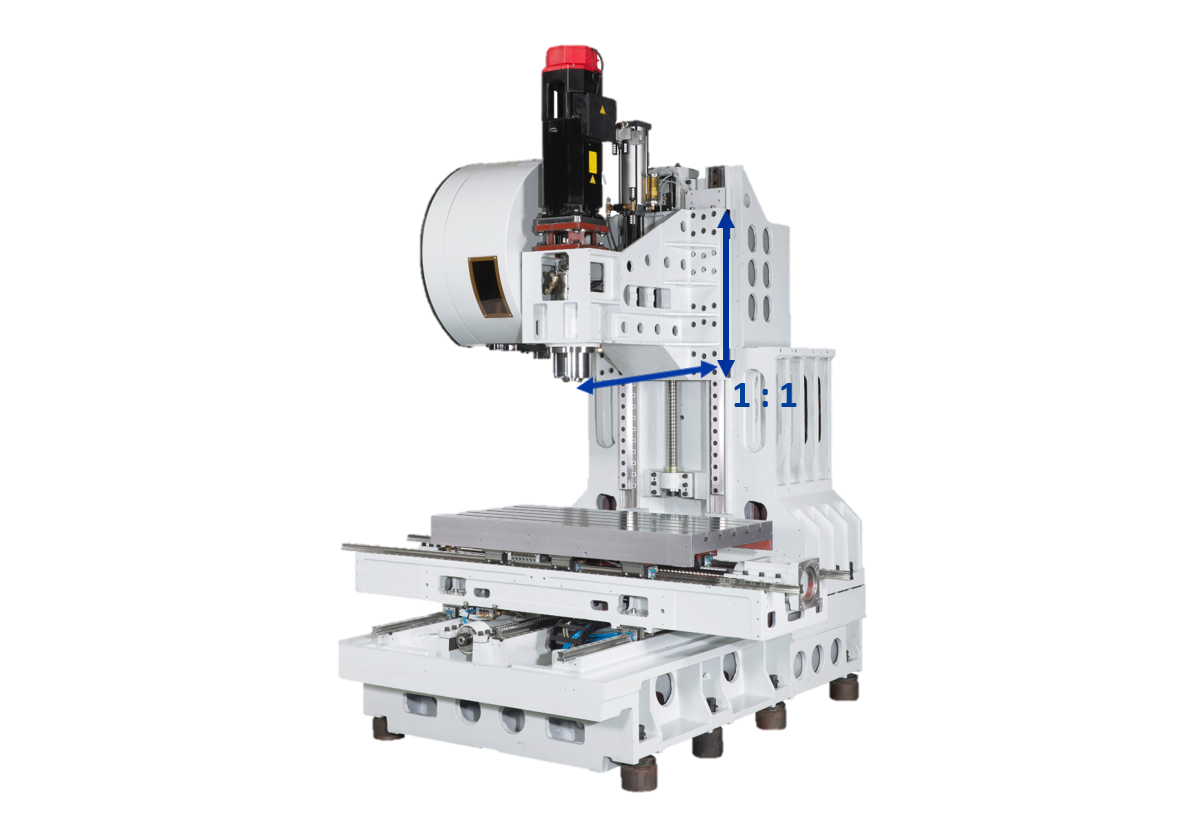

02High Rigidity Headstock

- Wide-span in headstock, The ratio of the length of the headstock combined with the column surface and spindle center to Z axis is 1:1. Z axis linear guideway with 6 blocks, greatly improve dynamic accuracy.

-

03Improve Accuracy Life, Tool Magazine Capacity Upgrade

- Tool magazine sit on the column, it can eliminate the influence from the weight of the tool magazine, and keep the accuracy.

- 24 tools ATC is standard. The second tool magazine is optional according to the capacity requirements of the automatic. Max. capacity is 60 tools.(30+30 tools) (OPT.)

-

04Frequency-controlled Tool Magazine

- Inverter controls the movement of the tool magazine motor, resistive braking, prevents abnormal braking operation, ensures smooth tool change.

-

05Z-axis Increased Travel Is Available (Opt.)

- Standard Z-axis travel is 610mm, it could be increased to 810mm with one-piece column, it is easy to install 4th or 5th axis rotary table, still can use the normal tool to machining after removing the rotary table, does not need to use special tool.

Model

FV1200

Table size

1200 x 600 mm

T slot

CD100 x 18 x 5 mm

Max. table load

800 kg

X axis

1200 mm

Y axis

660 mm

Z axis

610 (810) mm

Dis. From spindle nose to table

85~695 (85~895) mm

Dis. From spindle center to Z axis telescopic cover

655 mm